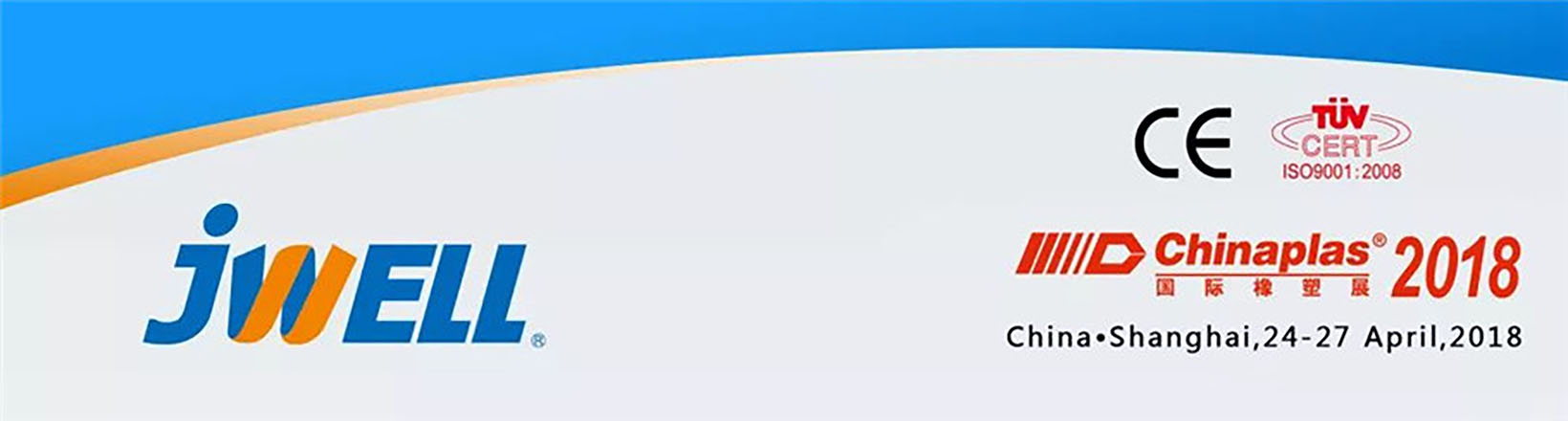

LVT soft composite floor by extruder extrusion floor base material, then through a set of six roller for base material and printing layer composite machine, wear-resisting layer, layer of compound at the same time, through the rolling tension, wear-resisting layer accurate control of preheating, to put the volume not wrinkle, does not shrink, deformation, extrusion compound high production efficiency, product quality is stable.

1. Green and Environmental Protection.

2. Super light and thin.

3. Super wear-resistance.

4. High elasticity and super shock resistance.

5. Super skid resistance.

6. Fireproof and flame resistance.

7. Waterproof and moistureproof.

8. Easy for cutting and splicing.

9. Easy installation.

10. Could laminate with WPC flooring directly.

LVT cork composite flooring production line is developed by Changzhou Jwell Plate&Sheet Equipment Co., LTD. through continuous innovation, which could replace the production mode of traditional laminating machine. This production line has the function of on-line compositing, on-line embossing, on-line tempering, etc. This line has the advantage of small floor occupation, high production efficiency, easy operation, etc.

1. On-line extruding line:

1.1. Extruder: SJZ80/156(Power 75KW).

1.2. Extrusion capacity: 2600 square meters/day.

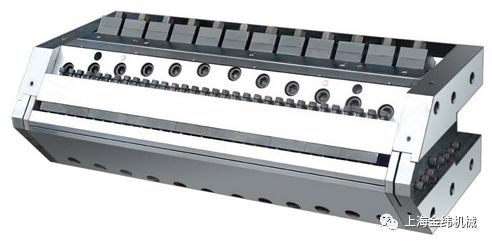

2. Mold:

2.1. The mold controlled by flow resisting bar, which could ensure quick adjustment and output evenly.

2.2. Could fine tuning the upper and down mold lip to better control the product's thickness.

3. Six-roller composite forming machine:

3.1. Use section composite design, which could reduce the stretching of surface's laminating material.

3.2. Innovative heating transitional roller could ensure the composition strength of thick wear-resisting layer.

3.3. The good installation design of embossing roller could ensure the good effect of embossing and more convenience to change the roller.

4. Tempering and water absorbing haul off unit.

4.1. Through the on-line tempering design, could control the product's flatness and shrinkage effectively.

4.2. Through the on-line tempering design, could control the product’s flatness and shrinkage effectively.

5. Automatic length fixing cutter.

5.1. The entrance of cutter have the design of auxiliary haul off, that could better control the cutter board's stability.

5.2. The special design of cutting could reduce the burrs of product's end face as much as possible.

5.3. The function of automatic length fixing could be operated easily and have high cutting precision.

Post time: Sep-11-2018