The features of line: it is based on 20 years screw designed experience of Shanghai Jwell Extrusion Machinery Co., Ltd, ensure the primary sheet line more stability and more higher output; by continuously improving the structure of XPE screw design, prompting the production line more high output, low energy consumption, wide width, foaming hole is tiny and so on many advantage, so in order to serve different customer's requirement, we have two sections of furnace and three sections of furnace for customer's option:

High efficiency: the output is increased by more than 30%, and the width of the product can reach 2200mm.

Energy saving: save gas 100 meters cubed /24h.

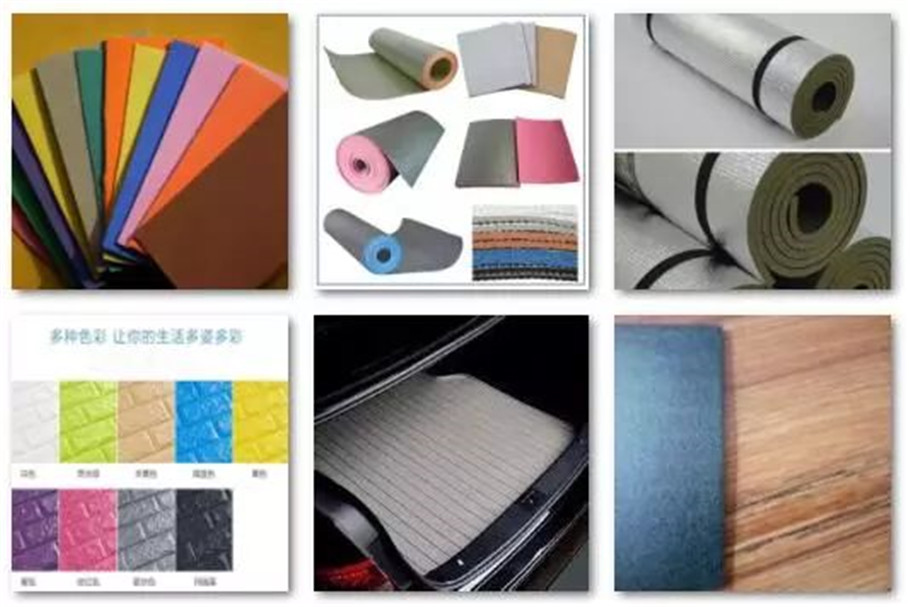

Application: product is focus on the car, sports and house decoration fields, it is ideal material for car foot mat and air condition for keeping warm.

Application field:

1. Application of automobile industry

Inside the car door guard plate, automobile waterproof door membrane, automobile door handrail lining, automobile ventilation pipe; Sunshade board, heat insulation pad, floor mat, luggage cushion; Seal friction parts.

2. Application of air conditioning industry

Air conditioning duct insulation, shock absorption, sound absorption. Air conditioning insulation pipe, drip pipe, compressor shock absorption, sound absorption, heat preservation.

3. Application of construction industry

Waterproof material, wall insulation, roof insulation and insulation materials, floor sound insulation cushion, etc.

4. Application in sports industry

XPE and IXPE are used in sports industry early, and are relatively common and mature. For example: sports mat, handle, cushion, camping mat, yoga mat, mat, climbing mat, sports lawn mat and various forms.

5. Application of shoe material and luggage industry

XPE and IXPE are used in the industry of shoes and bags to replace EPE as the inner core material.

6. Application of floating materials, toys and leisure industry

XPE, IXPE as floating material, can be processed into lifejacket, swimming ring, floating board, surfboard, leisure rowing, etc. XPE and IXPE are easy to take shape, and they can produce the best base material for toys and leisure products without deformation and non-toxic and harmless features.

Post time: Sep-11-2018