PET PP PA POY FDY BCF spinning machine

Video

POY Spinning Machine

Application

This machine is mainly used for spinning 30-330dtex polyester POY.

Main features

● Adopts LTM type pin screw, domestic-made continuous melt CPF, thus extend the service life of spin packs.

● Both top-mounted and bottom-mounted high-pressure rectangular and cup-shaped spin packs are available.

● Unique planetary spinning pump and separately driving finish oil pump.

● Evo and Cross Quench System with equably and stable flowing speed.

● Individually controlled, imported inverter and components.

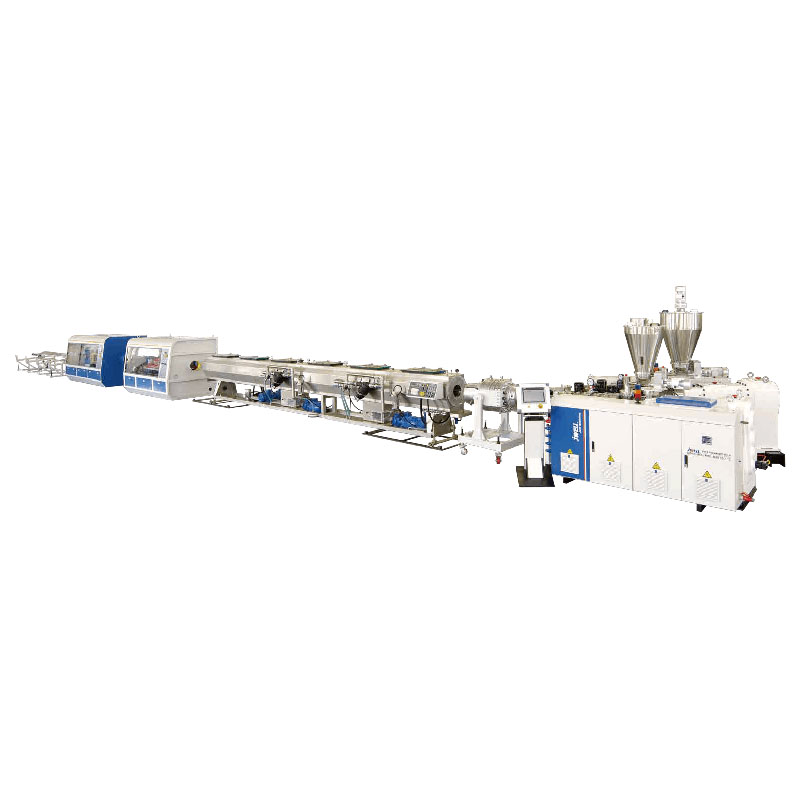

PP FDY Spinning Machine

Main features

● This machine uses PP as raw material and integrates extrusion, spinning, side blowing, drafting, and winding to produce PP polypropylene filament.

● Output and configuration can be designed according to user requirements.

● The overall investment is small, the investment cycle is short, and the spinning operation is convenient.

● According to user requirements, we can design and produce polypropylene general-strength, medium-strength, and high-strength yarns.

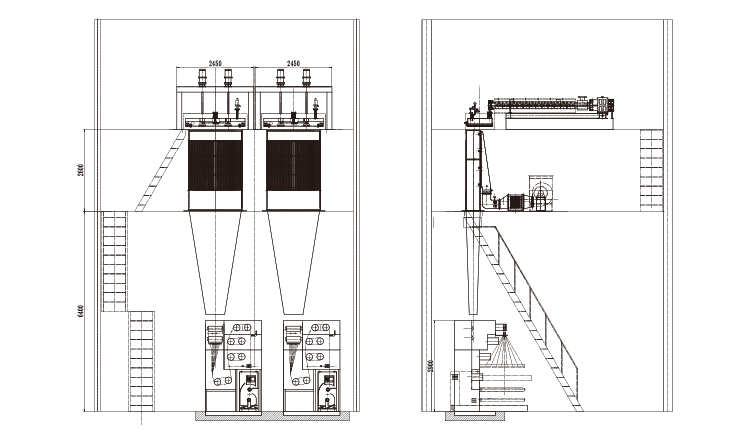

● According to the needs of users, a special spinning building or an overall steel structure can be designed.

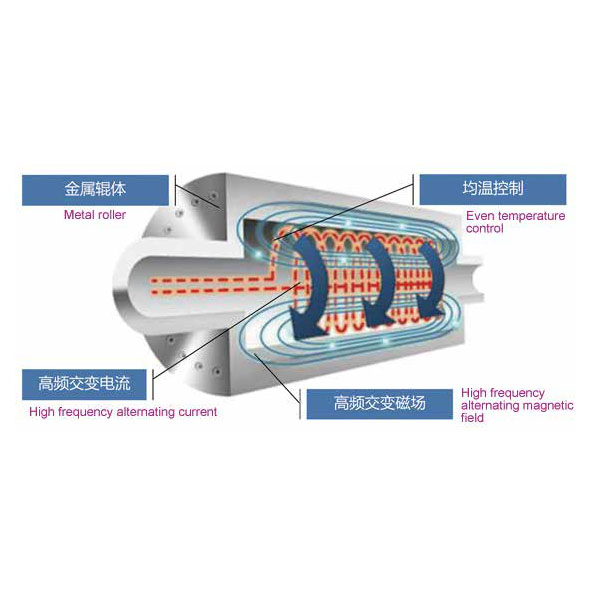

● The high-precision steam heating method is adopted to ensure that the temperature control accuracy of the heat roller surface is 1.5°.

● Adopt a special hot roller arrangement form to ensure the strength and tension of polypropylene fiber.

● A specially designed cooling side blowing device is adopted to ensure the uniformity of the thread drying.

● The electrical control adopts imported brand inverters, temperature control instruments, and imported rotary transmitters, and the control is accurate and reliable.

● Equipped with an automatic switching winder for precise winding, high switching success, and excellent silk cake forming.

Main technical parameters

● Suitable spinning range: 200D- 2000D

● Mechanical speed: 1800-2800m/min

● Position: 1800mm

● Number of heads per person: 6/8/12/16

● Spinneret diameter: 120mm/140mm/160mm

● Component form: rectangular component

● Heat roller diameter: medium 220*400mm

● Winding head: optional JWA1380/JWA1500/JWA1680 fully automatic switching winding head

PET-FDY Spinning Machine

Application

Suitable for CP spinning or Chips spinning to produce PET-FDY yarn.

Main features

● Uniform and stable quenching chamber system, to get good uster value.

● Finishing spray system for denier filament and universal oil wheel feeding system.

● Imported high precision inverter and imported high precision temperature controlling meter with setting, temperature controlling,monitoring and recording functions.

● Equipped with JW series precision winding and auto-doffing winder produced by Shanghai Jwell Chemical Fiber Machinery Co.,Ltd, high succssfully of doffing, fineness of bobbin shape, and good function of unwinding.

PA Spinning Machine

Application

This machine is mainly used for chips spinning of PA6 and PA66.

Main features

● Adopt new type of bimetal, barrel and special manifold design.

● Energy-saving spin beam, equipped with bottom-mounted, high-pressure cylinder spin pack.

● Unique planetary spinning pump and separately driving finish oil pump. With well-designed air suction device for mono-mer.

● Uniform front dismountable quenching chamber and unique nozzle type oil adding device.

● Equipped with precision winding and high speed auto-doffing winders, high succssfully of doffing, fineless of bobbin shape, and good function of unwinding.

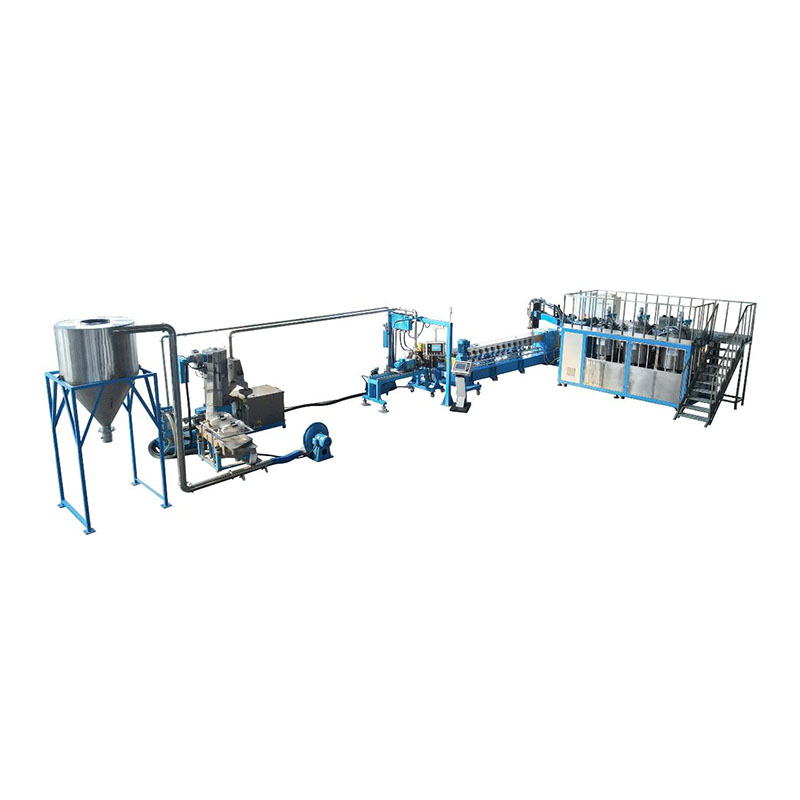

100% PET Bottle Flakes For POY Spinning Production Line.

Application

Special designed screw and Pre-CPF, producing qualified POY filament yarn by 100% PET bottle flakes.

Brief introduction

● This machine adopts the equipment manufactured by Jwell itself and the most advanced technology. It features the following characteristics manufacturing spandex by means of melting method.

● Adopting specialized spandex screw extruder and A.C inverter drive system.

● Unique crossing additive adding system with the patent in China.

● New type spin beam and high precision planetary pumps.

● Novel, reliable, uniform and stable quenching chamber system.

● Finish oil spraying and driving system which are suitable for spandex yarn.

● Imported high precision inverter with imported high precision temperature controlling meter.

● Specialized manual or fully automatic spandex winder. (equipped with JW3PA, JW3PB, JW470, JW460 and JW690 etc.)

PET Bottle Flake Poy Spinning Machine

Application

Special designed screw and Pre-CPF, producing qualified POY filament yarn by 100% PET bottle flakes.

Brief introduction

● This machine adopts the equipment manufactured by Jwell itself and the most advanced technology. It features the following characteristics manufacturing spandex by means of melting method.

● Adopting specialized spandex screw extruder and A.C inverter drive system.

● Unique crossing additive adding system with the patent in China.

● New type spin beam and high precision planetary pumps.

● Novel, reliable, uniform and stable quenching chamber system.

● Finish oil spraying and driving system which are suitable for spandex yarn.

● Imported high precision inverter with imported high precision temperature controlling meter.

● Specialized manual or fully automatic spandex winder. (equipped with JW3PA, JW3PB, JW470, JW460 and JW690 etc.)

Technical features

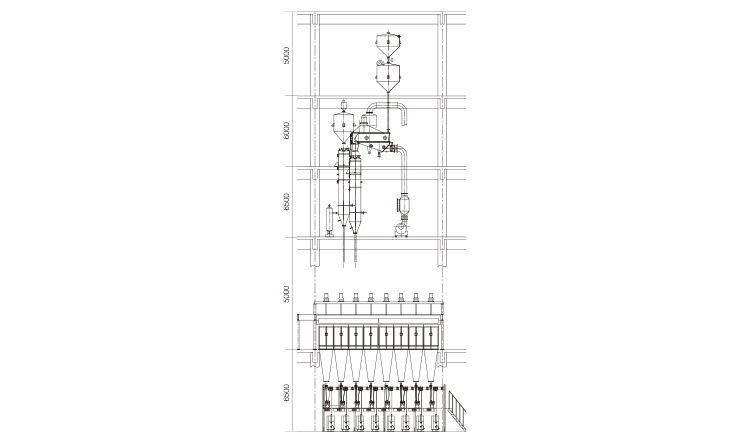

● Special screw and barrel design, suitable for spinning recycled materials.

● The two-stage filter is equipped with a booster pump to ensure the uniform delivery of the melt pressure and the filtering effect.

● Using a new type of special spinning box for recycling, high efficiency, energy-saving, and environmental protection.

● Using bottom-mounted cup-shaped components to improve the uniformity of melt flow.

● Special air blowing system on the return side, honeycomb structure, uniform and stable wind speed, good drying.

PA6+PET Composite Filament Spinning Machine

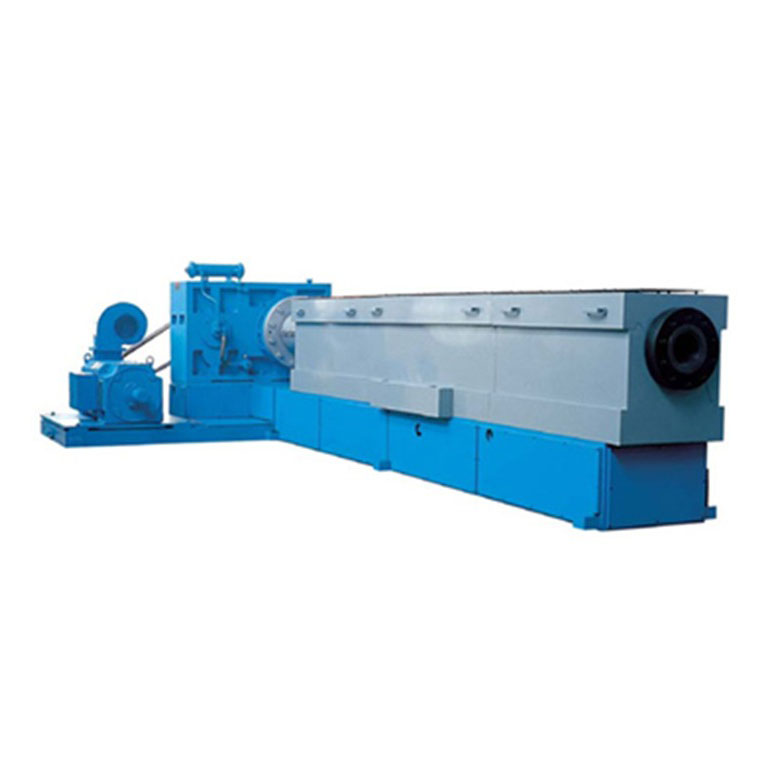

This machine is suitable for the production of polyester and polyamide type; co-spinning, center and split thin type; POY composite long filament of orange petal type or specialized yarn type etc.Adopting two groups of JWM series of screw extruders, with A.C inverter drive and LTM pin screw.

Two groups of melt distribution pipelines with static mixer can be connected with continuous CPF.Separately temperature controlled spin beam of two cases with freezing valves, two groups of metering pump driving system and precise planetary pumps. Top-mounted or bottom-mounted composite spin packs and various composite spinneret.

Uniform and stable quenching chamber system. Oil finish spray and driving system.

Two groups of uniform and reliable dowtherm heating system. Imported high precision inverter and imported high precision temperature controlling meters with setting, temperature controlling,

monitoring and recording functions.

Adopting solid adhibiting and pressing melt yarn, various multilevel drawn industrial yarn manufactured through high speed winding.

Spinning denier range: 400-3000D 2 ends, 4 ends, 6 ends, 8 ends, 12 ends or 16 ends in each position 4 sets, 6 sets or 8 sets of hot godet for each position with compact configuration. Adopting domestic automatic winders With excellent quality, large output, low cost and optimizing performance & price ratio

Spinning Machines Factory Gallery

PET PP PA POY FDY BCF spinning machine

FAQ

● International Commercial Terms(Incoterms): FOB, CFR, CIF, EXW.

● Terms of Payment: LC, T/T.

● Average Lead Time: Peak season lead time: 3-6 months, Off season lead time: 1-3 months.

● Number of Foreign Trading Staff:>50 People.

Yes, We own 5 manufacturing bases and sales center in Shanghai, Suzhou, Changzhou, Zhou Shan, Dongguan China.

Jwell made the first Chinese screw and barrel in 1978 in brand name Jinhailuo. After more than 40 years development.

JWELL is one of the biggest extrusion machine supplier in China with 300design&test engineer, 3000 employees.

Jwell has become the premier supplier of extrusion lines and reliable business partners. Welcome to drop in us.

Our machines taking the European standards and follow the Germany type of business, we cooperation with International famous brands Siemens Schneider Flender Omron ABB WEG Falk Fuji etc. Our company continuously imports over 1000 international first-class high precision processing equipment such as multistage machining centers, CNC lathes and CNC milling machines from Korea, Japan etc. All our processes strictly adhere to CE certification, IS09001 and 2008 quality management system. And we have 12 months quality warranty time. We testing the machine performances before each delivery. Jwell service engineers will always be here for anything you needed.

Usually it takes about 1 – 4 months depends on different machinery upon receipt of order advance payment.

Once clear your requirements and determined extrusion line is ideal for you. We will send technical solutions and Proforma Invoice to you. You can pay via TT bank transfer, LC as you like.

One. We provide both customized extrusion lines and technical solutions. Welcome contact with us for technical innovation or improvements for your future purchasing plan.

We produce more than 2000 advanced extrusion lines every year world wide.

We can send the small spare parts by air express for urgent matter. And the complete production line by sea to save the cost. You can either use your own assigned shipping agent or our cooperative forwarder. The nearest port is China Shanghai, Ningbo port, which is convenient for maritime transportation..

Yes, we support our business partners by pre-after sale service. Jwell has more than 300 technical testing engineers traveling world wide. Any cases would be responded with prompt solutions. We provide training, testing, operation and maintenance service for a life time.

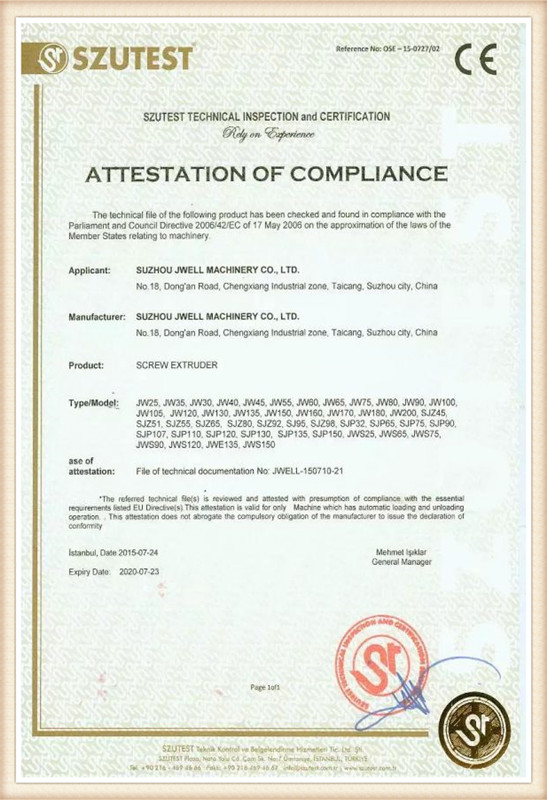

Certificates

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: Other

Design, Development, Manufacture And Sales Of Intellectual Property Rights Management For Plastic Machine

2016-06-14 ~ 2019-06-13

Certified By: Other

Design, Development, Manufacture And Sales Of Plastic Pipe And Sheet Extrusion Production Line

2018-11-20 ~ 2021-11-19

Certified By: Quality Austria Training, Certification and Evaluation Ltd.

Plastic Extrusion Line

2010-01-29 ~